TECHNOLOGY THAT PERFORMS

Milled Face & Back

Milling the face and back surfaces is a high-precision process, unobtainable through forging alone, that ensures every line, curve, and angle are produced to exacting specifications to create a high-performance body design and enhancing aesthetics.

Precision Weighting

One large weight is located near the CG on the back of the clubhead. This large center weight can be used to achieve optimal swing weight. Unique to PXG, customers can experience the benefits of these adjustments during an in-person fitting. Weighting is not intended to be adjusted after purchase.

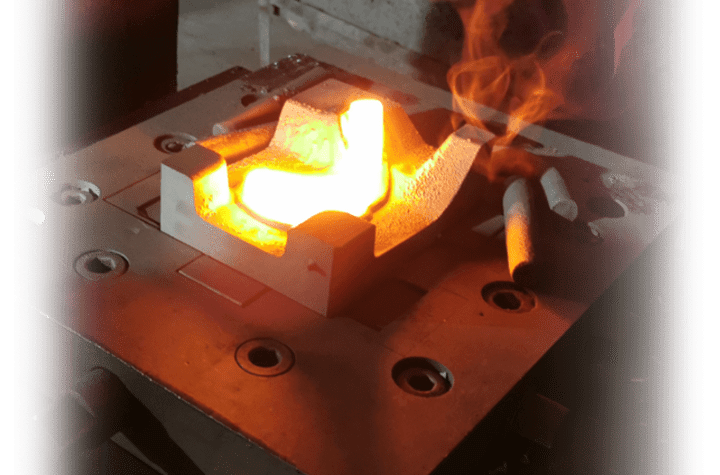

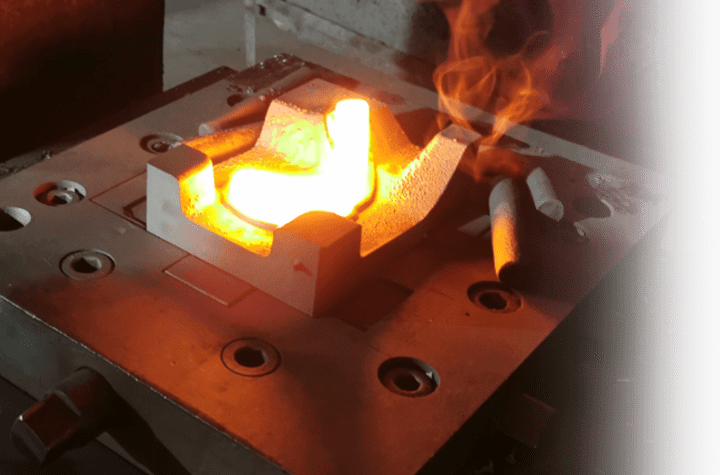

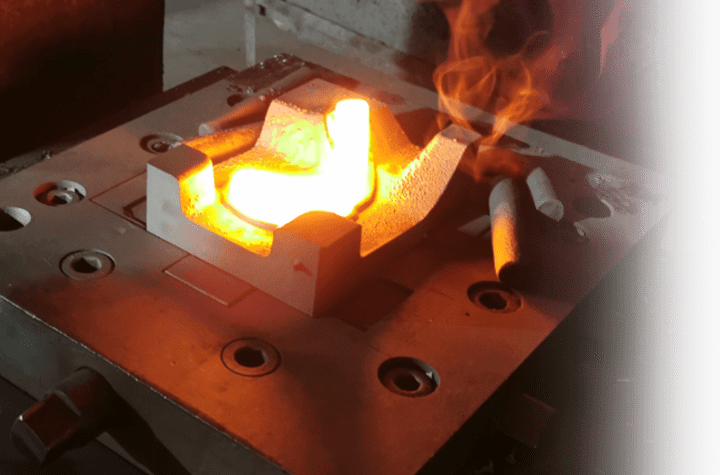

3X Forged Feel

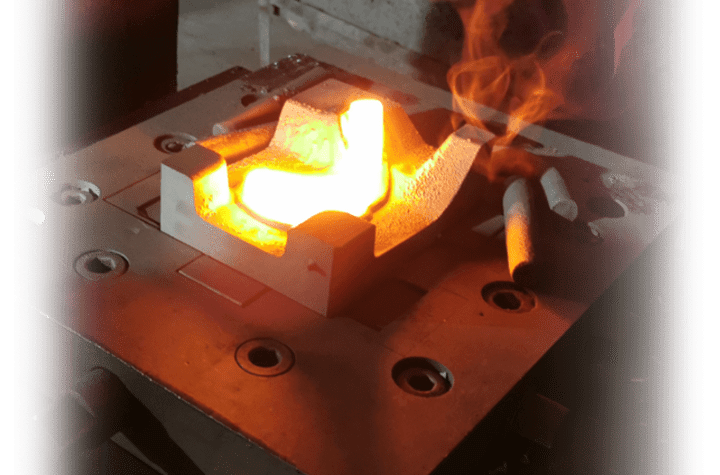

Each iron is three-times forged from 8620 soft carbon steel, creating a tight grain structure that increases its strength, prolonging the life of the grooves and enhancing the overall feel and appearance.

Robotic Precision

0317 CB Players Irons undergo a high-precision robotic polishing process. Robotic polishing creates an extremely precise manufacturing process that ensures consistent sole and face perimeter geometry with every club.

Xtreme Dark Finish

PXG’s stunning Xtreme Dark irons are created using an advanced process called Diamond-like Carbon (DLC) coating. DLC significantly extends the reasonable lifetime of the finish. Unlike the typical black PVD used by other equipment manufacturers, DLC is a three-layer process that produces extraordinary wear resistance without influencing club performance.

technology that performs

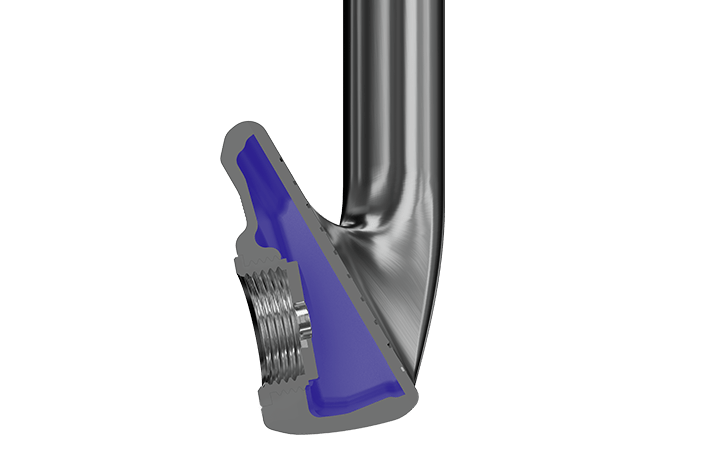

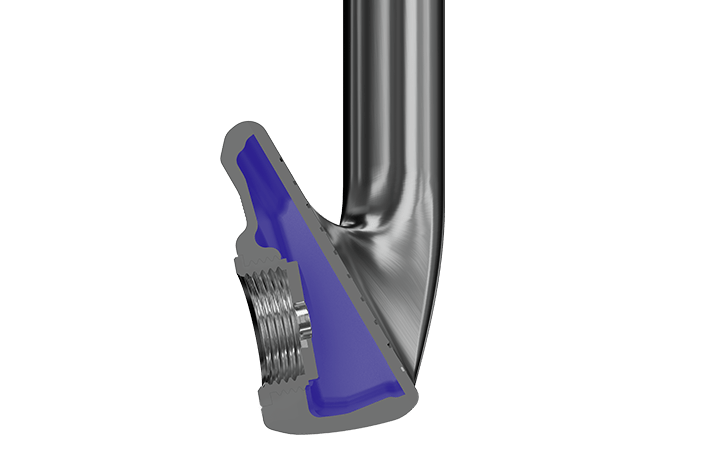

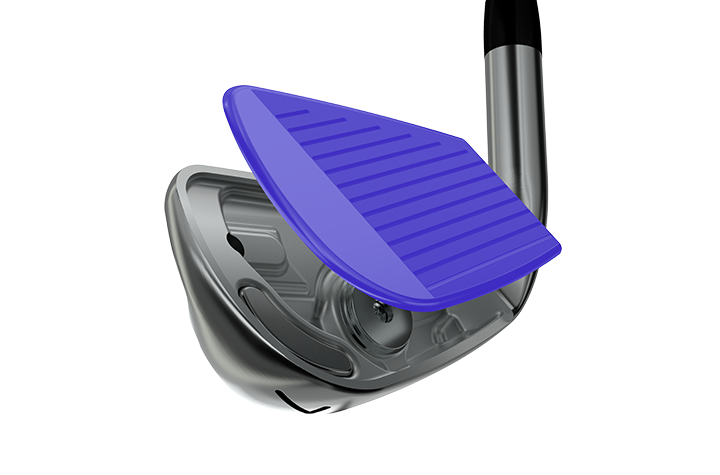

NEW QuantumCOR Technology

10 years in the making, PXG’s extremely lightweight new proprietary core material – QuantumCOR – helps reduce the mass

Variable Ultra-Thin Maraging Steel Face

Since their inception, PXG irons have maintained the thinnest face in golf, and with GEN7 the face is now even thinner. Made from high-strength HT1770 maraging steel, the variable ultra-thin face measures a mere 0.050” (~1.27mm) thick — 15% thinner than previous models. Combined with PXG’s proprietary core material, GEN7 Irons deliver a C.O.R. performance that pushes the USGA limit, helping increase distance and forgiveness while also enhancing sound and feel.

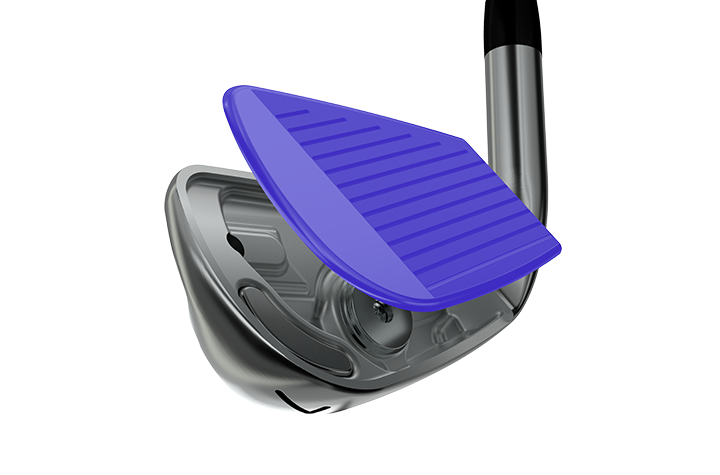

POWER CHANNEL TECHNOLOGY

Power Channel Technology is the proprietary U-shaped corridor built into the internal surface of the club face to increase deflection and bend in the top sector. The channel creates face movement and transfers energy to simultaneously increase launch angle, trajectory, and ball speed.

Titanium bezel technology

A lightweight titanium insert, used to provide housing for the Precision Weighting Technology, removes mass from the center of the club in order to redistribute weight to the perimeter to boost MOI.

INTERNAL TUNGSTEN WEIGHTING

GEN7 Irons feature internal 20-gram toe mass tungsten weighting that balance the Center of Gravity (CG) location in the center of the face while boosting Moment of Inertia (MOI) to increase forgiveness.

PRECISION WEIGHTING TECHNOLOGY

One large weight is located near the CG on the back of the clubhead. This large center weight can be used to achieve optimal swing weight. Unique to PXG, customers can experience the benefits of these adjustments during an in-person fitting. Weighting is not intended to be adjusted after purchase.

5X FORGED

Each iron is five-times forged from 8620 soft carbon steel, creating a tight grain structure that increases its strength, prolonging the life of the grooves and enhancing the overall feel and appearance.

MILLED BACK SURFACE

Milling the back surface of each iron is a high-precision process that reduces the wall thickness more than forging alone could achieve, to create a high-performance body design and an enhanced aesthetic.

PXG 0317 CB IRON SPECS

| Club | Loft | Standard Length (inches) | Standard Lie | Offset (inches) | Bounce |

|---|---|---|---|---|---|

| 3 | 21° | 39.5″ | 60.5° | .135″ | 4° |

| 4 | 24° | 38.875″ | 61° | .120″ | 5° |

| 5 | 27° | 38.25″ | 61.5° | .105″ | 6° |

| 6 | 30° | 37.625″ | 62° | .090″ | 7° |

| 7 | 33° | 37″ | 62.5° | .075″ | 8° |

| 8 | 37° | 36.5″ | 63° | .060″ | 10° |

| 9 | 42° | 36″ | 63.5° | .045″ | 12° |

| W | 46° | 35.75″ | 64° | .030″ | 14° |

| G | 50° | 35.5″ | 64° | .020″ | 14° |

specs